Tips for Printing the Best Images

September 26, 2019

National Newspaper Week

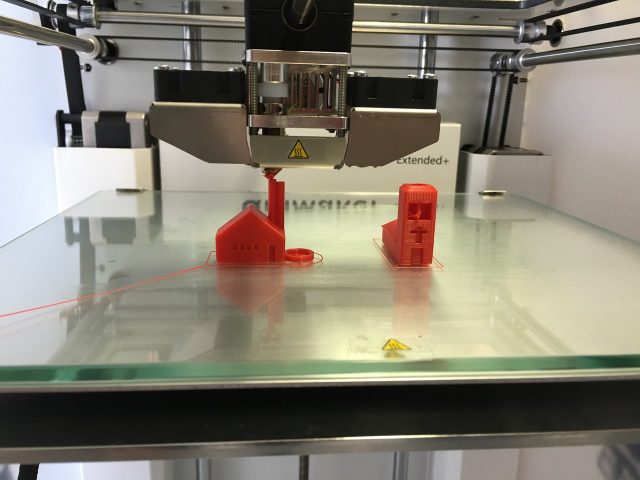

October 3, 20193D printing has the potential to change the world in amazing ways. Scientists are already experimenting in ways to 3D print organs for transplant patients. But what will the technology mean for the average office?

3D printing offers many opportunities for office workers to change the way they work – not least in the way we source the things we need to get work done.

Speed and Convenience

One of the most frequently touted benefits 3D printing is already delivering is in the sourcing of spare parts. When the office printer breaks, for example, rather than sending off for new parts to be sent out to us, 3D printing makes it possible for us to print those parts as and when we need them.

With companies such as Samsung beginning to make 3D print files available to customers, customers now find themselves able to print replacement parts for personal use.

As well as transforming the supply chain, this offers huge potential for businesses to extend the life of aging and legacy equipment. When it is no longer commercially viable for a manufacturer to mass-produce parts, they can simply release the 3D files to customers to print as required.

Speed and convenience are the main drivers here. But 3D printing also offers potential to improve quality and opens the door for additional flexibility and customization.

Quality and Customization

Because it is as cost-effective to 3D print one item as it is to 3D print many, customization no longer comes at the expense of profit.

Businesses will be able to adapt their designs to the specifications of individual customers – making “batch size one” a reality. This makes 3D printing a powerful tool for developing loyalty and deeper collaborations with your customers.

It’s this aspect of 3D printing that also makes it an ideal solution for prototyping work. For any business involved in manufacturing, 3D printing is a natural fit. Not only will it help designers to test ideas and create prototypes quickly, it can be used to produce the dies and tooling for traditional manufacturing processes – a traditionally costly and time-consuming part of a product’s route to market.

Additive manufacturing is very different to traditional subtractive methods – opening up possibilities to make things differently (and better!). One important example of this is in the manufacture of metal parts for aeroplanes. 3D printing makes it possible to produce complex honeycomb structures that are more lightweight without sacrificing strength – an innovation that improves an aeroplane’s fuel efficiency.

Another example might be the production of color-coded layers within a part which can indicate wear. This simple change has the potential to transform maintenance schedules.

Grasping the Opportunities

Potential exists for businesses in many areas:

- Streamline the supply chain; printing replacement parts

- Extend the life of the equipment

- Improve product design, making it faster and cheaper

- Reduce lead times

- Introduce customization to improve service and build customer loyalty

- Produce one-offs and small runs for which a premium can be charged

- Add new features or experiment with new materials

While 3D printing remains a new technology for most businesses, success will be found by working with an experienced partner, who can guide you about the machines, design practices, 3D print materials and processes, and opportunities for enhancement that 3D printing can offer.